The Impact of Robotics and Factory Automation in the Aerospace Manufacturing Sector

Industrial robotics and factory automation have shaped the modern landscape of aerospace manufacturing and fabrication services.

Today’s highly advanced flight industries demand the utmost in precision and consistency from their products. At the same time, these projects often require high-volume capacity and/or rapid turnaround times for production. Achieving all of those goals while remaining price-competitive requires innovative contract manufacturing solutions integrated with factory automation and robotics.

The Advantages of Robotics and Factory Automation for Aerospace Manufacturing

- Faster production speed and quicker project turnaround.

- Higher volume capacity and “lights out” around-the-clock manufacturing.

- Higher levels of precision and consistency for complex, close-tolerance aerospace components.

- A more robust supply chain based on a domestic manufacturing source for your products.

Three Ways Robotics and Factory Automation Are Utilized in Modern Aerospace Manufacturing

Robotic Welding Services

Robotic welding is critical to streamlining aerospace fabrication projects while maintaining precision weld quality. Aerospace welding is a highly repetitive process that requires absolute accuracy and consistency.

Robotic welding systems achieve much higher levels of productivity than human welders while achieving the same or better quality. Since aerospace welding can be a hazardous and intensive process, automated welding solutions also help improve the safety of our employees when compared to manual welding.

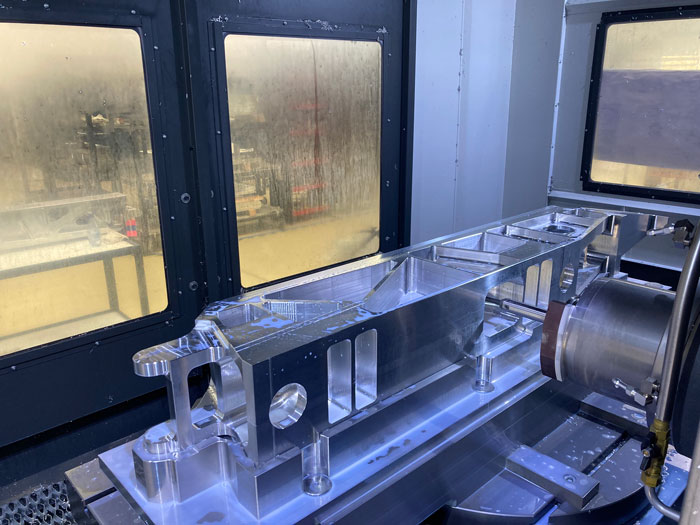

Automated Aerospace Assembly

Automating the assembly process will significantly streamline your aerospace project. Drilling, tapping, and fastening operations require a large amount of tedious work for manual operators – especially in the case of large airplane components like fuselages, body panels, chassis sections, and other structural assemblies. Robotic assembly systems automate the entire process – from tapping and drilling to reaming and threading – reducing labor costs while maintaining absolute quality.

Put simply, many aerospace components require a vast number of custom-drilled holes and fasteners in order to securely install within the aircraft. Automating the drilling, fastening, and various assembly processes will drastically cut down your production time.

Automated Inspection and Quality Control Solutions

Today’s aviation and spaceflight sectors almost invariably demand close tolerances and extremely strict quality requirements. In other words, consistent quality assurance is absolutely critical. At the same time, detailed inspection procedures can add a lot of additional time to your production schedule.

Robot inspection systems are utilized to perform various non-destructive testing procedures such as ultrasonic testing, imaging, and metrology inspections. These automated quality control systems ensure precision with every product while minimally delaying the manufacturing process.

Over 65 Years of Precision Aerospace Manufacturing Services

Founded in 1966, Snowline has continually adopted the industry’s most capable production equipment to remain as one of America’s leading aerospace manufacturers. Located in Sacramento, California, our state-of-the-art facility is integrated with some of today’s most advanced robotic manufacturing equipment and factory automation systems.