3 Questions to Ask Before Starting a CNC Production Machining Project

Choosing the right CNC machinist is essential to ensure the overall success of your CNC production machining project – especially in the case of highly customized machining services for complex, high-precision components. Not every run-of-the-mill CNC machine shop will be able to truly meet your specifications and quality standards, even if their listed machining capabilities and tolerances check out.

In today’s aerospace market, many projects demand a manufacturer that goes above and beyond in terms of both quality and customer support. That level of attention and service is especially crucial for full-scale production runs and high-volume machining, in which any manufacturing issues can quickly compound and completely derail your project.

So when you contract out your custom CNC machining project, you have to perform careful research, request quotes and, above all, thoroughly discuss all details of your products and their unique application. That will guarantee all of the right policies and processes are in place before any metal hits the production line.

On that note, here are three important questions you should think about as you consider your contract manufacturing options.

1. Do you simply need a manufacturer, or full-scale production?

Before you even begin researching aerospace machine shops, you should bring the scope of your project into full perspective. To that end, one of the first questions you should consider is whether you need a basic manufacturer or a total production service provider.

Throughout the industry today, it’s common for customers to use the terms “manufacturing” and “production” interchangeably. However, there are some critical differences to consider:

The Difference Between Production and Manufacturing Services:

Essentially, manufacturing converts raw materials into finished products through the use of advanced tools like CNC machines. A basic manufacturer will turn your designs and specifications into finished products, but will remain otherwise uninvolved in your project.

In contrast, production is a much broader term that includes all of the overarching processes and services associated with manufacturing. Production typically consists of scheduling and controlling the allocation of all resources needed for your project. That includes facility management, labor, the actual machining services, as well as the allocation of raw materials and individual components into secondary production processes. In other words, production includes all of the human labor, the machinery, materials and processes that we use to create a finished product.

As a full-service production machining company, Snowline can truly take your project from concept to completion.

2. What secondary services are needed for your CNC machining project?

In order to streamline your project as much as possible, you should choose a CNC machining company that also provides all of the required secondary production processes. For example, additional sheet metal work, custom welding services, or turnkey assembly solutions are often required to turn custom machined components into fully functional end products.

Before you choose a CNC machining service provider, you should therefore weigh the costs (along with the time and logistics) of contracting out these secondary services compared to partnering with a single-source manufacturer such as Snowline.

3. What certifications or quality control processes do your products require?

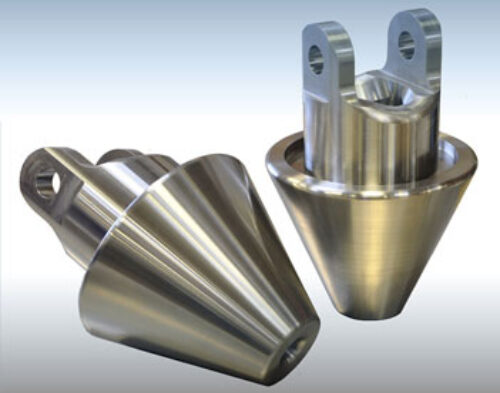

Different types of CNC machining projects come with drastically different regulatory requirements and quality control expectations. For example, custom aerospace components often demand extremely complex machined features produced with absolute precision, while basic CNC turned rods and shafts are much easier to produce.

Before you choose a CNC machining company, it’s important to fully understand the certifications and quality control processes that your products will ultimately require.

An ISO 9001:2015 and AS9100D Certified CNC Machining Company:

Snowline is an AS9100D certified aerospace manufacturer specializing in precision welding services. Additionally, our company is ISO 9001:2015 certified to further assure the quality of our products and processes. These certifications are crucial for customers seeking better consistency and guaranteed results from their contract manufacturer.

An American Production Machine Shop Specializing in Precision Aerospace Manufacturing

Snowline is proud to serve as one the nation’s leading aerospace machining service providers. Our company offers complete, turnkey manufacturing and assembly solutions designed to streamline your project and simplify your supply chain. Based out of Sacramento, California, we have provided quality-backed, full-service production solutions since 1966.