AWS D17.1 and D1.6 Welding Services: Precision Aerospace Products Built to Code

AWS D17.1 and D1.6 Welding Services: Precision Aerospace Products Built to Code

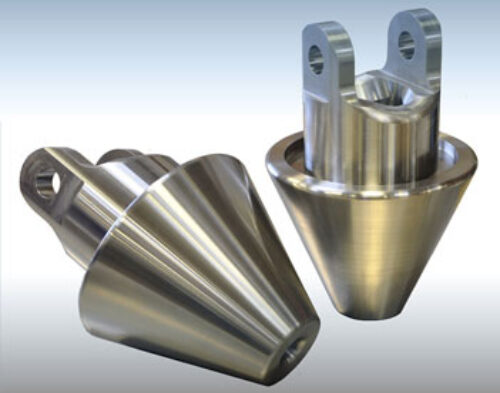

Modern aerospace components typically demand some combination of high precision, high strength, and/or highly complex designs. Consistently meeting those requirements necessitates meticulous welding processes guided by strict codes and a rigorous quality control system. For aerospace welding projects, that typically means AS9100 certified manufacturing, as well as various AWS certified welding processes.

In a previous article, we provided an overview of the AWS D17.1 standard – what it means in terms of our operations and aerospace fabrication in general. Similarly, we discussed the AWS D1.6 standard for aerospace manufacturing.

However, what exactly do these standards mean when it comes to your end products? Let’s take a look.

AWS Standards Ensure High-Strength, Precision-Built End Products

The AWS D1.6 structural welding code for stainless steel covers welding for critical aerospace applications. High strength and structural integrity must be ensured, as passengers’ lives may literally depend on the reliability of these products. The D1.6 standard thus ensures your end products meet or exceed the specified requirements in durability, corrosion resistance, and overall structural integrity.

Similarly, the AWS D17.1 standard for aerospace fusion welding and non-destructive examination (NDE). Following the code ensures that welds meet stringent requirements in precision, strength, and defect minimization. It requires expertise in all aspects of fabrication, from product design to materials science, thus ensuring all welds reach the required strength of your end product specifications.

AWS D17.1 Ensuring Your Aerospace Products Are Built to Code

Many of today’s aerospace projects require compliance with strict regulatory bodies such as FAA, DoD, or NASA specifications. Welding services which meet AWS standards such as D17.1 and D1.6 are often essential to meet the regulations governing your end products.

However, you’ll find an additional benefit in establishing a partnership with an experienced aerospace manufacturer that knows the industry from the inside. Beyond simply building your products, Snowline brings more than half a century of experience to the table which helps us navigate the regulatory requirements and manage your project as cost-effectively as possible.

Superior and Certified Aerospace Manufacturing Solutions

Snowline is an AS9100D certified aerospace manufacturer with multiple welding processes certified to AWS 17.1 and AWS D1.6 standards. Additionally, our quality control system is certified to ISO 9001:2015 standards. These certifications are crucial for our customers seeking better consistency and guaranteed results from their contract manufacturer.

Located in Cameron Park, California, Snowline’s precision fabrication solutions have helped aircraft and spaceflight projects get off the ground since 1966.